Water purification facts for kids

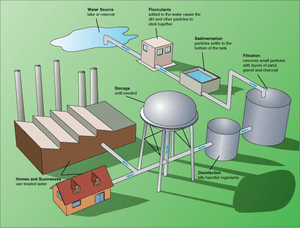

Water purification is the process of removing undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water fit for specific purposes. Most water is purified and disinfected for human consumption (drinking water), but water purification may also be carried out for a variety of other purposes, including medical, pharmacological, chemical, and industrial applications. The methods used include physical processes such as filtration, sedimentation, and distillation; biological processes such as slow sand filters or biologically active carbon; chemical processes such as flocculation and chlorination; and the use of electromagnetic radiation such as ultraviolet light.

Water purification may reduce the concentration of particulate matter including suspended particles, parasites, bacteria, algae, viruses, and fungi as well as reduce the concentration of a range of dissolved and particulate matter.

Governments usually dictate the standards for drinking water quality. These standards will require minimum / maximum set points of contaminants and the inclusion of control elements that produce drinking water. Quality standards in many countries require specific amounts of disinfectant (such as chlorine) in the water after it leaves the water treatment plant (WTP), to reduce the risk of re-contamination while the water is in the distribution system.

It is not possible to tell whether water is safe to drink just by looking at it. Simple procedures such as boiling or the use of a household activated carbon filter are not sufficient for treating all the possible contaminants that may be present in water from an unknown source. Chemical analysis, while expensive, is the only way to obtain the information necessary for deciding on method of purification.

According to a 2007 World Health Organization (WHO) report, 1.1 billion people lack access to an improved drinking water supply; 88% of the 4 billion annual cases of diarrheal disease are attributed to unsafe water and inadequate sanitation and hygiene, while 1.8 million people die from diarrheal disease each year. The WHO estimates that 94% of these diarrheal disease cases are preventable through modifications to the environment, including access to safe water. Simple techniques for treating water at home, such as chlorination, filters, and solar disinfection, and for storing it in safe containers could save a huge number of lives each year. Reducing deaths from waterborne diseases is a major public health goal in developing countries.

Contents

Types of water

- Groundwater

The water emerging from some deep ground water may have fallen as rain many decades, hundreds, thousands or in some cases millions of years ago. Soil and rock layers naturally filter the ground water to a high degree of clarity before it is pumped to the treatment plant. Such water may emerge as springs, artesian springs, or may be extracted from boreholes or wells. Deep ground water is generally of very high bacteriological quality (i.e., pathogenic bacteria or the pathogenic protozoa are typically absent), but the water typically is rich in dissolved solids, especially carbonates and sulfates of calcium and magnesium. Depending on the strata through which the water has flowed, other ions may also be present including chloride, and bicarbonate. There may be a requirement to reduce the iron or manganese content of this water to make it pleasant for drinking, cooking, and laundry use. Disinfection may also be required. Where groundwater recharge is practised, it is equivalent to lowland surface waters for treatment *Upland lakes and reservoirs Typically located in the headwaters of river systems, upland reservoirs are usually sited above any human habitation and may be surrounded by a protective zone to restrict the opportunities for contamination. Bacteria and pathogen levels are usually low, but some bacteria, protozoa or algae will be present. Where uplands are forested or peaty, humic acids can colour the water. Many upland sources have low pH which require adjustment.

- Rivers, canals and low land reservoirs

Low land surface waters will have a significant bacterial load and may also contain algae, suspended solids and a variety of dissolved constituents.

- Atmospheric water generation

It is a new technology that can provide high quality drinking water by extracting water from the air by cooling the air and thus condensing water vapour.

- Rainwater harvesting or fog collection

Collects water from the atmosphere can be used especially in areas with significant dry seasons and in areas which experience fog even when there is little rain.

Taking the salt out of seawater.

Treatment

Goals

The goals of the treatment are to remove unwanted constituents in the water and to make it safe to drink or fit for a specific purpose in industry or medical applications. The choice of method will depend on the quality of the water being treated, the cost of the treatment process and the quality standards expected of the processed water.

The processes below are the ones commonly used in water purification plants. Some or most may not be used depending on the scale of the plant and quality of the raw (source) water.

Pre-treatment

- Pumping and containment - The majority of water must be pumped from its original location (such as a sandbox or a gutter) and then it is directed into pipes or holding tanks. To avoid adding contaminants to the water, this physical infrastructure must be made from appropriate materials and constructed so that accidental contamination does not occur.

- Screening (see also screen filter) - The first step in purifying surface water is to remove large debris such as sticks, leaves, trash and other large particles which may interfere with subsequent purification steps. Most deep groundwater does not need screening before other purification steps.

- Storage - Water from rivers may also be stored in bankside reservoirs for periods between a few days and many months to allow natural biological purification to take place. This is especially important if treatment is by slow sand filters. Storage reservoirs also provide a buffer against short periods of drought or to allow water supply to be maintained during transitory pollution incidents in the source river.

- Pre-conditioning - Many waters rich in hardness salts are treated with soda-ash (Sodium carbonate) to precipitate calcium carbonate out utilising the common ion effect.

- Pre-chlorination - In many plants the incoming water was chlorinated to minimize the growth of fouling organisms on the pipe-work and tanks. Because of the potential adverse quality effects (see chlorine below), this has largely been discontinued.

pH adjustment

Distilled water has an pH of 7 (neither alkaline nor acidic) and sea water has an average pH of 8.3 (slightly alkaline). If the water is acidic (lower than 7), lime or soda ash is added to raise the pH.

Flocculation

Flocculation is a process which clarifies the water. Clarifying means removing any turbidity or colour so that the water is clear and colourless. Clarification is done by causing a precipitate to form in the water which can be removed using simple physical methods. Initially the precipitate forms as very small particles but as the water is gently stirred, these particles stick together to form bigger particles - this process is sometimes called flocculation. Many of the small particles that were originally present in the raw water absorb onto the surface of these small precipitate particles and so get incorporated into the larger particles that coagulation produces. In this way the coagulated precipitate takes most of the suspended matter out of the water and is then filtered off, generally by passing the mixture through a coarse sand filter or sometimes through a mixture of sand and granulated anthracite (high carbon and low volatiles coal). Coagulants or flocculating agents that may be used include:

- Iron (III) hydroxide

- Aluminium hydroxide

- Aluminium hydroxychloride

Sedimentation

Water exiting the flocculation basin may enter the sedimentation basin, also called a clarifier or settling basin. It is a large tank with slow flow, allowing floc to settle to the bottom. The minimum clarifier retention time is normally 4 hours. In effect, large particles sweep vertically though the basin and clean out smaller particles on their way to the bottom.

As particles settle to the bottom of the basin a layer of sludge is formed on the floor of the tank. This layer of sludge must be removed and treated. The tank may be equipped with mechanical cleaning devices that continually clean the bottom of the tank or the tank can be taken out of service when the bottom needs to be cleaned.

Filtration

After separating most floc, the water is filtered as the final step to remove remaining suspended particles and unsettled floc. The most common type of filter is a rapid sand filter. Water moves vertically through sand which often has a layer of activated carbon or anthracite coal above the sand. The top layer removes organic compounds, which contribute to taste and odour.

The space between sand particles is larger than the smallest suspended particles, so simple filtration is not enough. Most particles pass through surface layers but are trapped in pore spaces or adhere to sand particles. Effective filtration extends into the depth of the filter. To clean the filter, water is passed quickly upward through the filter, opposite the normal direction (called backflushing or backwashing) to remove embedded particles. Prior to this, compressed air may be blown up through the bottom of the filter to break up the compacted filter media to aid the backwashing process; this is known as air scouring.

Advantages:

- Filters out much smaller particles than paper and sand filters can.

- Filters out virtually all particles larger than their specified pore sizes.

- They are quite thin and so liquids flow through them fairly rapidly.

- They are reasonably strong and so can withstand pressure differences across them of typically 2-5 atmospheres.

- They can be cleaned (back flushed) and reused.

Membrane filters are widely used for filtering both drinking water and sewage (for reuse). For drinking water, membrane filters can remove virtually all particles larger than 0.2 um--including Giardia and cryptosporidium. Membrane filters are an effective form of tertiary treatment when it is desired to reuse the water for industry, for limited domestic purposes, or before discharging the water into a river that is used by towns further downstream. They are widely used in industry, particularly for beverage preparation (including bottled water). However no filtration can remove substances that are actually dissolved in the water such as phosphorus, nitrates and heavy metal ions.

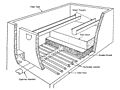

Slow sand filters

Slow sand filters may be used where there is sufficient land and space as the water must be passed very slowly through the filters. These filters rely on biological treatment processes for their action rather than physical filtration. The filters are carefully constructed using graded layers of sand with the coarsest sand, along with some gravel, at the bottom and finest sand at the top. Drains at the base convey treated water away for disinfection. Filtration depends on the development of a thin biological layer, called the zoogleal layer or Schmutzdecke, on the surface of the filter. An effective slow sand filter may remain in service for many weeks or even months if the pre-treatment is well designed and produces water with a very low available nutrient level which physical methods of treatment rarely achieve. Very low nutrient levels allow water to be safely sent through distribution system with very low disinfectant levels thereby reducing consumer irritation over offensive levels of chlorine and chlorine by-products. Slow sand filters are not backwashed; they are maintained by having the top layer of sand scraped off when flow is eventually obstructed by biological growth.

A specific 'large-scale' form of slow sand filter is the process of bank filtration, in which natural sediments in a riverbank are used to provide a first stage of contaminant filtration. While typically not sufficiently clean enough to be used directly for drinking water, the water gained from the associated extraction wells is much less problematic than river water taken directly from the major streams where bank filtration is often used.

Lava filters

Lava filters are similar to sand filters and may also only be used where there is sufficient land and space. Like sand filters, the filters rely on biological treatment processes for their action rather than physical filtration. Unlike slow sand filters however, they are constructed out of 2 layers of lava pebbles and a top layer of nutrient-free soil (only at the plant roots). On top, water-purifying plants (as Iris pseudacorus and Sparganium erectum) are placed. Usually, around 1/4 of the dimension of lavastone is required to purify the water and just like slow sand filters, a series of herringbone drains are placed (with lava filters these are placed at the bottom layer).

Removal of ions and other dissolved substances

Ultrafiltration membranes use polymer membranes with chemically formed microscopic pores that can be used to filter out dissolved substances avoiding the use of coagulants. The type of membrane media determines how much pressure is needed to drive the water through and what sizes of micro-organisms can be filtered out.

Ion exchange: Ion exchange systems use ion exchange resin- or zeolite-packed columns to replace unwanted ions. The most common case is water softening consisting of removal of Ca2+ and Mg2+ ions replacing them with benign (soap friendly) Na+ or K+ ions. Ion exchange resins also used to remove toxic ions such as nitrate, nitrite, mercury, arsenic-containing ions, and many others.

Electrodeionization: Water is passed between a positive electrode and a negative electrode. Ion exchange membranes allow only positive ions to migrate from the treated water toward the negative electrode and only negative ions toward the positive electrode. High purity deionized water is produced with a little worse degree of purification in comparison with ion exchange treatment. Complete removal of ions from water is regarded as electrodialysis. The water is often pre-treated with a reverse osmosis unit to remove non-ionic organic contaminants.

Other mechanical and biological techniques

In addition to the many techniques used in large-scale water treatment, several small-scale, less (or non)-polluting techniques are also being used to treat polluted water. These techniques include those based on mechanical and biological processes. An overview:

- mechanical systems: sand filtration, lava filter systems and systems based on UV-radiation)

- biological systems:

- plant systems as constructed wetlands and treatment ponds (sometimes incorrectly called reedbeds) and living walls) and

- compact systems as activated sludge systems, biorotors, aerobic and anaerobic biofilters, submerged aerated filters, and biorolls

In order to purify the water adequately, several of these systems are usually combined to work as a whole. Combination of the systems is done in two to three stages, namely primary and secondary purification. Sometimes tertiary purification is also added.

Disinfection

Disinfection is accomplished both by filtering out harmful microbes and also by adding disinfectant chemicals in the last step in purifying drinking water. Water is disinfected to kill any pathogens which pass through the filters.

- Chlorination- The most common disinfection method is some form of chlorine or its compounds such as chloramine or chlorine dioxide. Chlorine is a strong oxidant that rapidly kills many harmful micro-organisms.

- Chlorine dioxide is another faster-acting disinfectant. It is, however, relatively rarely used, because in some circumstances it may create excessive amounts of chlorite, which is a by-product regulated to low allowable levels in the United States.

- Chloramines are another chlorine-based disinfectant.

- Ozone (O3) is an unstable molecule, a "free radical" of oxygen which readily gives up one atom of oxygen providing a powerful oxidising agent which is toxic to most waterborne organisms. It is a very strong, broad spectrum disinfectant that is widely used in Europe.

- UV radiation (light) is very effective at inactivating cysts, as long as the water has a low level of colour so the UV can pass through without being absorbed. The main disadvantage to the use of UV radiation is that, like ozone treatment, it leaves no residual disinfectant in the water.

- Hydrogen peroxide is another disinfectant. It works similar to ozone, yet activators as formic acid are to be added to increase the working of this chemical substance. It also has the disadvantages that it is slow-working, phytotoxic in high dosage, and decreases the PH of the water it purifies.

Images for kids

-

Drinking water pollution detector Rainbow trout (Oncorhynchus mykiss) are being used in water purification plants to detect acute water pollution

See also

In Spanish: Purificación de agua potable para niños

In Spanish: Purificación de agua potable para niños