Pottery facts for kids

Pottery is the ceramic material which makes up potteryware. Major types include earthenware, stoneware and porcelain. The place where such wares are made is also called a pottery (plural "potteries"). Pottery also refers to the art or craft of a potter or the making of pottery. A dictionary definition is simply clay fired in a kiln.

Pottery objects are made from damp clay mixed with other materials. They are then fired in a special oven called a kiln at high temperatures. Firing makes the clay hard. The potter may then apply a glaze to the surface before firing the object again. The fired glaze makes the surface of the pottery shiny, decorative and water-tight.

Some potters make objects which are not useful and are really artistic objects or sculpture. Bare pottery objects without a glaze are called bisque or just earthenware. The finest pottery objects, made of porcelain or bone china are quite strong, yet are translucent.

Contents

History of pottery

Pottery originated before the Neolithic period. The earliest example we have is from eastern Europe, dating to 25,000 years ago or earlier. It is a female figurine known as the Venus of Dolní Věstonice, from a palaeolithic site in Moravia, Czech Republic. It may have been made as part of a fertility ritual. There are some similar figures from other nearby sites.

Since the invention of agriculture, and the building of cities, containers for food and drink have been found at almost all archaeological sites.

Methods of shaping

Hand-shaping methods

Pottery can be shaped by a range of methods that include:

Hand building. This is the earliest forming method. Wares can be constructed by hand from coils of clay, combining flat slabs of clay, or pinching solid balls of clay or some combination of these. Parts of hand-built vessels are often joined together with the aid of slip, an aqueous suspension of clay body and water. Hand-building is slower than wheel-throwing, but it offers the potter a high degree of control over the size and shape of wares. The speed and repetitiveness of other techniques is more suitable for making precisely matched sets of wares such as tablewares although some studio potters find hand-building more conducive to create one-of-a-kind works of art.

The potter's wheel. In a process called "throwing" (coming from the Old English word thrawan which means to twist or turn, a ball of clay is placed in the center of a turntable, called the wheel-head, which the potter rotates with a stick, with foot power or with a variable-speed electric motor.

During the process of throwing, the wheel rotates rapidly while the solid ball of soft clay is pressed, squeezed and pulled gently upwards and outwards into a hollow shape. The first step of pressing the rough ball of clay downward and inward into perfect rotational symmetry is called centering the clay--a most important skill to master before the next steps: opening (making a centered hollow into the solid ball of clay), flooring (making the flat or rounded bottom inside the pot), throwing or pulling (drawing up and shaping the walls to an even thickness), and trimming or turning (removing excess clay to refine the shape or to create a foot).

Considerable skill and experience are required to throw pots of an acceptable standard and, while the ware may have high artistic merit, the reproducibility of the method is poor. Because of its inherent limitations, throwing can only be used to create wares with radial symmetry on a vertical axis. These can then be altered by impressing, bulging, carving, fluting, and incising. In addition to the potter's hands these techniques can use tools, including paddles, anvils & ribs, and those specifically for cutting or piercing such as knives, fluting tools and wires. Thrown pieces can be further modified by the attachment of handles, lids, feet and spouts.

Mass-production methods

Granulate pressing: As the name suggests, this is the operation of shaping pottery by pressing clay in a semi-dry and granulated condition in a mould. The clay is pressed into the mould by a porous die through which water is pumped at high pressure. The granulated clay is prepared by spray-drying to produce a fine and free-flowing material having a moisture content of between about 5 and 6 per cent. Granulate pressing, also known as dust pressing, is widely used in the manufacture of ceramic tiles and, increasingly, of plates.

Injection Moulding: is a shape-forming process adapted for the tableware industry from the method long established for the forming of thermoplastic and some metal components. It has been called Porcelain Injection Moulding, or PIM. Suited to the mass production of complex-shaped articles, one significant advantage of the technique is that it allows the production of a cup, including the handle, in a single process, and thereby eliminates the handle-fixing operation and produces a stronger bond between cup and handle. The feed to the mould die is a mix of approximately 50 to 60 percent unfired body in powder form, together with 40 to 50 percent organic additives composed of binders, lubricants and plasticisers. The technique is not as widely used as other shaping methods.

Jiggering and jolleying: These operations are carried out on the potter's wheel and allow the time taken to bring wares to a standardized form to be reduced. Jiggering is the operation of bringing a shaped tool into contact with the plastic clay of a piece under construction, the piece itself being set on a rotating plaster mould on the wheel. The jigger tool shapes one face while the mould shapes the other. Jiggering is used only in the production of flat wares, such as plates, but a similar operation, jolleying, is used in the production of hollow-wares such as cups. Jiggering and jolleying have been used in the production of pottery since at least the 18th century. In large-scale factory production, jiggering and jolleying are usually automated, which allows the operations to be carried out by semi-skilled labor.

Roller-head machine: This machine is for shaping wares on a rotating mould, as in jiggering and jolleying, but with a rotary shaping tool replacing the fixed profile. The rotary shaping tool is a shallow cone having the same diameter as the ware being formed and shaped to the desired form of the back of the article being made. Wares may in this way be shaped, using relatively unskilled labor, in one operation at a rate of about twelve pieces per minute, though this varies with the size of the articles being produced. Developed in the U.K. just after World War II by the company Service Engineers, roller-heads were quickly adopted by manufacturers around the world; they remain the dominant method for producing flatware.

Pressure casting – specially developed polymeric materials allow a mould to be subject to application external pressures of up to 4.0 MPa–so much higher than slip casting in plaster moulds where the capillary forces correspond to a pressure of around 0.1 - 0.2 MPa. The high pressure leads to much faster casting rates and, hence, faster production cycles. Furthermore, the application of high pressure air through the polymeric moulds upon demoulding the cast means a new casting cycle can be started immediately in the same mould, unlike plaster moulds which require lengthy drying times. The polymeric materials have much greater durability than plaster and, therefore, it is possible to achieve shaped products with better dimensional tolerances and much longer mould life. Pressure casting was developed in the 1970s for the production of sanitaryware although, more recently, it has been applied to tableware.

RAM pressing: A factory process for shaping table wares and decorative ware by pressing a bat of prepared clay body into a required shape between two porous molding plates. After pressing, compressed air is blown through the porous mould plates to release the shaped wares.

Slipcasting: is often used in the mass production of ceramics and is ideally suited to the making of wares that cannot be formed by other methods of shaping. A slip, made by mixing clay body with water, is poured into a highly absorbent plaster mold. Water from the slip is absorbed into the mould leaving a layer of clay body covering its internal surfaces and taking its internal shape. Excess slip is poured out of the mold, which is then split open and the molded object removed. Slipcasting is widely used in the production of sanitary wares and is also used for making smaller articles, such as intricately detailed figurines.

Decorating and glazing

Pottery may be decorated in a number of ways including:

- In the clay body, for example, by incising patterns on its surface.

- Underglaze decoration (in the manner of many blue and white wares).

- In-glaze decoration

- On-glaze decoration

- Enamel

Additives can be worked into the clay body prior to forming, to produce desired effects in the fired wares. Coarse additives such as sand and grog (fired clay which has been finely ground) are sometimes used to give the final product a required texture. Contrasting coloured clays and grogs are sometimes used to produce patterns in the finished wares. Colorants, usually metal oxides and carbonates, are added singly or in combination to achieve a desired colour. Combustible particles can be mixed with the body or pressed into the surface to produce texture.

Agateware: Named after its resemblance to the quartz mineral agate which has bands or layers of colour that are blended together, agatewares are made by blending clays of differing colours together but not mixing them to the extent that they lose their individual identities. The wares have a distinctive veined or mottled appearance. The term "agateware" is used to describe such wares in the United Kingdom; in Japan the term "neriage" is used and in China, where such things have been made since at least the Tang Dynasty, they are called "marbled" wares. Great care is required in the selection of clays to be used for making agatewares as the clays used must have matching thermal movement characteristics.

Banding: This is the application by hand or by machine of a band of colour to the edge of a plate or cup. Also known as "lining", this operation is often carried out on a potter's wheel.

Burnishing: The surface of pottery wares may be burnished prior to firing by rubbing with a suitable instrument of wood, steel or stone to produce a polished finish that survives firing. It is possible to produce very highly polished wares when fine clays are used or when the polishing is carried out on wares that have been partially dried and contain little water, though wares in this condition are extremely fragile and the risk of breakage is high.

Engobe: This is a clay slip, that is used to coat the surface of pottery, usually before firing. Its purpose is often decorative though it can also be used to mask undesirable features in the clay to which it is applied. Engobe slip may be applied by painting or by dipping to provide a uniform, smooth, coating. Engobe has been used by potters from pre-historic times until the present day and is sometimes combined with sgraffito decoration, where a layer of engobe is scratched through to reveal the colour of the underlying clay. With care it is possible to apply a second coat of engobe of a different colour to the first and to incise decoration through the second coat to expose the colour of the underlying coat. Engobes used in this way often contain substantial amounts of silica, sometimes approaching the composition of a glaze.

Litho: This is a commonly-used abbreviation for lithography, although the alternative names of transfer print or "decal" are also common. These are used to apply designs to articles. The litho comprises three layers: the colour, or image, layer which comprises the decorative design; the cover coat, a clear protective layer, which may incorporate a low-melting glass; and the backing paper on which the design is printed by screen printing or lithography. There are various methods of transferring the design while removing the backing-paper, some of which are suited to machine application.

Gold: Decoration with gold is used on some high quality ware. Different methods exist for its application, including:

- Best gold - a suspension of gold powder in essential oils mixed with a flux and a mercury salt extended. This can be applied by a painting technique. From the kiln, the decoration is dull and requires burnishing to reveal the full colour

- Acid Gold – a form of gold decoration developed in the early 1860s at the English factory of Mintons Ltd, Stoke-on-Trent. The glazed surface is etched with diluted hydrofluoric acid prior to application of the gold. The process demands great skill and is used for the decoration only of ware of the highest class.

- Bright Gold – consists of a solution of gold sulphoresinate together with other metal resonates and a flux. The name derives from the appearance of the decoration immediately after removal from the kiln as it requires no burnishing

- Mussel Gold – an old method of gold decoration. It was made by rubbing together gold leaf, sugar and salt, followed by washing to remove solubles

Glazing

Glaze is a glassy coating on pottery, the primary purposes of which are decoration and protection. One important use of glaze is to render porous pottery vessels impermeable to water and other liquids. Glaze may be applied by dusting the unfired composition over the ware or by spraying, dipping, trailing or brushing on a thin slurry composed of the unfired glaze and water. The colour of a glaze before it has been fired may be significantly different than afterward. To prevent glazed wares sticking to kiln furniture during firing, either a small part of the object being fired (for example, the foot) is left unglazed or, alternatively, special refractory "spurs" are used as supports. These are removed and discarded after the firing.

Some specialised glazing techniques include:

- Salt-glazing, where common salt is introduced to the kiln during the firing process. The high temperatures cause the salt to volatize, depositing it on the surface of the ware to react with the body to form a sodium aluminosilicate glaze. In the 17th and 18th centuries, salt-glazing was used in the manufacture of domestic pottery. Now, except for use by some studio potters, the process is obsolete. The last large-scale application before its demise in the face of environmental clean air restrictions was in the production of salt-glazed sewer-pipes.

- Ash glazing - ash from the combustion of plant matter has been used as the flux component of glazes. The source of the ash was generally the combustion waste from the fuelling of kilns although the potential of ash derived from arable crop wastes has been investigated. Ash glazes are of historical interest in the Far East although there are reports of small-scale use in other locations such as the Catawba Valley Pottery in the United States. They are now limited to small numbers of studio potters who value the unpredictability arising from the variable nature of the raw material.

Firing

Firing produces irreversible changes in the body. It is only after firing that the article or material is pottery. In lower-fired pottery, the changes include sintering, the fusing together of coarser particles in the body at their points of contact with each other. In the case of porcelain, where different materials and higher firing-temperatures are used, the physical, chemical and mineralogical properties of the constituents in the body are greatly altered. In all cases, the object of firing is to permanently harden the wares and the firing regime must be appropriate to the materials used to make them.

The atmosphere within a kiln during firing can affect the appearance of the finished wares.

Kilns may be heated by burning wood, coal and gas or by electricity.

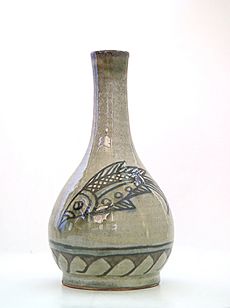

Images for kids

-

Forming a vessel using a potter's wheel

-

Earthenware pottery from the Neolithic Longshan culture, China, 3rd millennium BC

-

An electric potter's wheel, with bat (green disk) and throwing bucket. Not shown is a foot pedal used to control the speed of the wheel, similar to a sewing machine

-

Pottery firing mound in Kalabougou, Mali. All the earliest pottery was made in firing pits of this sort

-

Contemporary pottery from the State of Hidalgo, Mexico

-

Two panels of earthenware tiles painted with polychrome glazes over a white glaze, Iran, first half of the 19th century.

-

An Incipient Jōmon pottery vessel reconstructed from fragments (10,000–8,000 BC), Tokyo National Museum, Japan

-

Pottery bowl from Jarmo, Mesopotamia, 7100–5800 BC.

-

Late Neolithic Manunggul Jar from Palawan used for burial, topped with two figures representing the journey of the soul into the afterlife.

-

Before the invention of pottery in Western Asia, during the Pre-Pottery Neolithic: jar in calcite alabaster, Syria, late 8th millennium BC.

-

A potter with his pottery wheel, British Raj (1910)

-

Bowl painted on slip under transparent glaze (polychrome), 9th or 10th century, Nishapur. National Museum of Iran.

-

Spherical Hanging Ornament, 1575–1585, Ottoman Period. Brooklyn Museum.

-

Chess set (Shatrang); Gaming pieces. 12th century, Nishapur glazed fritware. Metropolitan Museum of Art

See also

In Spanish: Alfarería para niños

In Spanish: Alfarería para niños