Supercapacitor facts for kids

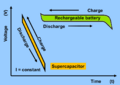

Supercapacitor is a quite new type of capacitor that has better ability to store energy. Some parts have thought that in future electric cars would use supercapacitors. This also means that mobile phones will be more efficient in holding their charge therefore regular charging will decrease.

Applications

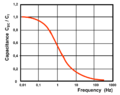

Supercapacitors do not support alternating current (AC) applications.

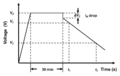

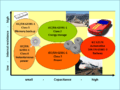

Supercapacitors have advantages in applications where a large amount of power is needed for a relatively short time, where a very high number of charge/discharge cycles or a longer lifetime is required. Typical applications range from milliamp currents or milliwatts of power for up to a few minutes to several amps current or several hundred kilowatts power for much shorter periods.

General

Consumer electronics

In applications with fluctuating loads, such as laptop computers, PDA's, GPS, portable media players, hand-held devices, and photovoltaic systems, supercapacitors can stabilize the power supply.

Supercapacitors deliver power for photographic flashes in digital cameras and for LED flashlights that can be charged in much shorter periods of time, e.g., 90 seconds.

Some portable speakers are powered by supercapacitors.

Tools

A cordless electric screwdriver with supercapacitors for energy storage has about half the run time of a comparable battery model, but can be fully charged in 90 seconds. It retains 85% of its charge after three months left idle.

Grid power buffer

Numerous non-linear loads, such as EV chargers, HEVs, air conditioning systems, and advanced power conversion systems cause current fluctuations and harmonics. These current differences create unwanted voltage fluctuations and therefore power oscillations on the grid. Power oscillations not only reduce the efficiency of the grid, but can cause voltage drops in the common coupling bus, and considerable frequency fluctuations throughout the entire system. To overcome this problem, supercapacitors can be implemented as an interface between the load and the grid to act as a buffer between the grid and the high pulse power drawn from the charging station.

Low-power equipment power buffer

Supercapacitors provide backup or emergency shutdown power to low-power equipment such as RAM, SRAM, micro-controllers and PC Cards. They are the sole power source for low energy applications such as automated meter reading (AMR) equipment or for event notification in industrial electronics.

Supercapacitors buffer power to and from rechargeable batteries, mitigating the effects of short power interruptions and high current peaks. Batteries kick in only during extended interruptions, e.g., if the mains power or a fuel cell fails, which lengthens battery life.

Uninterruptible power supplies (UPS) may be powered by supercapacitors, which can replace much larger banks of electrolytic capacitors. This combination reduces the cost per cycle, saves on replacement and maintenance costs, enables the battery to be downsized and extends battery life.

Supercapacitors provide backup power for actuators in wind turbine pitch systems, so that blade pitch can be adjusted even if the main supply fails.

Voltage stabilizer

Supercapacitors can stabilize voltage fluctuations for powerlines by acting as dampeners. Wind and photovoltaic systems exhibit fluctuating supply evoked by gusting or clouds that supercapacitors can buffer within milliseconds. Also, similar to electrolytic capacitors, supercapacitors are also placed along the power lines to consume reactive power and improve the AC power factor in a lagging power flow circuit. This would allow for a better used real power to produced power and make the grid overall more efficient.

Micro grids

Micro grids are usually powered by clean and renewable energy. Most of this energy generation, however, is not constant throughout the day and does not usually match demand. Supercapacitors can be used for micro grid storage to instantaneously inject power when the demand is high and the production dips momentarily, and to store energy in the reverse conditions. They are useful in this scenario, because micro grids are increasingly producing power in DC, and capacitors can be utilized in both DC and AC applications. Supercapacitors work best in conjunction with chemical batteries. They provide an immediate voltage buffer to compensate for quick changing power loads due to their high charge and discharge rate through an active control system. Once the voltage is buffered, it is put through an inverter to supply AC power to the grid. It is important to note that supercapacitors cannot provide frequency correction in this form directly in the AC grid.

Energy harvesting

Supercapacitors are suitable temporary energy storage devices for energy harvesting systems. In energy harvesting systems, the energy is collected from the ambient or renewable sources, e.g., mechanical movement, light or electromagnetic fields, and converted to electrical energy in an energy storage device. For example, it was demonstrated that energy collected from RF (radio frequency) fields (using an RF antenna as an appropriate rectifier circuit) can be stored to a printed supercapacitor. The harvested energy was then used to power an application-specific integrated circuit (ASIC) circuit for over 10 hours.

Incorporation into batteries

The UltraBattery is a hybrid rechargeable lead-acid battery and a supercapacitor. Its cell construction contains a standard lead-acid battery positive electrode, standard sulphuric acid electrolyte and a specially prepared negative carbon-based electrode that store electrical energy with double-layer capacitance. The presence of the supercapacitor electrode alters the chemistry of the battery and affords it significant protection from sulfation in high rate partial state of charge use, which is the typical failure mode of valve regulated lead-acid cells used this way. The resulting cell performs with characteristics beyond either a lead-acid cell or a supercapacitor, with charge and discharge rates, cycle life, efficiency and performance all enhanced.

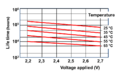

Street lights

Sado City, in Japan's Niigata Prefecture, has street lights that combine a stand-alone power source with solar cells and LEDs. Supercapacitors store the solar energy and supply 2 LED lamps, providing 15 W power consumption overnight. The supercapacitors can last more than 10 years and offer stable performance under various weather conditions, including temperatures from +40 to below -20 °C.

Medical

Supercapacitors are used in defibrillators where they can deliver 500 joules to shock the heart back into sinus rhythm.

Transport

Aviation

In 2005, aerospace systems and controls company Diehl Luftfahrt Elektronik GmbH chose supercapacitors to power emergency actuators for doors and evacuation slides used in airliners, including the Airbus 380.

Military

Supercapacitors' low internal resistance supports applications that require short-term high currents. Among the earliest uses were motor startup (cold engine starts, particularly with diesels) for large engines in tanks and submarines. Supercapacitors buffer the battery, handling short current peaks, reducing cycling and extending battery life.

Further military applications that require high specific power are phased array radar antennae, laser power supplies, military radio communications, avionics displays and instrumentation, backup power for airbag deployment and GPS-guided missiles and projectiles.

Automotive

Toyota's Yaris Hybrid-R concept car uses a supercapacitor to provide bursts of power. PSA Peugeot Citroën has started using supercapacitors as part of its stop-start fuel-saving system, which permits faster initial acceleration. Mazda's i-ELOOP system stores energy in a supercapacitor during deceleration and uses it to power on-board electrical systems while the engine is stopped by the stop-start system.

Bus/tram

Maxwell Technologies, an American supercapacitor-maker, claimed that more than 20,000 hybrid buses use the devices to increase acceleration, particularly in China. Guangzhou, In 2014 China began using trams powered with supercapacitors that are recharged in 30 seconds by a device positioned between the rails, storing power to run the tram for up to 4 km — more than enough to reach the next stop, where the cycle can be repeated.

Energy recovery

A primary challenge of all transport is reducing energy consumption and reducing CO2 emissions. Recovery of braking energy (recuperation or regeneration) helps with both. This requires components that can quickly store and release energy over long times with a high cycle rate. Supercapacitors fulfill these requirements and are therefore used in a lot of applications in all kinds of transportation.

Railway

Supercapacitors can be used to supplement batteries in starter systems in diesel railroad locomotives with diesel-electric transmission. The capacitors capture the braking energy of a full stop and deliver the peak current for starting the diesel engine and acceleration of the train and ensures the stabilization of line voltage. Depending on the driving mode up to 30% energy saving is possible by recovery of braking energy. Low maintenance and environmentally friendly materials encouraged the choice of supercapacitors.

Cranes, forklifts and tractors

Mobile hybrid Diesel-electric rubber tyred gantry cranes move and stack containers within a terminal. Lifting the boxes requires large amounts of energy. Some of the energy could be recaptured while lowering the load, resulting in improved efficiency.

A triple hybrid forklift truck uses fuel cells and batteries as primary energy storage and supercapacitors to buffer power peaks by storing braking energy. They provide the fork lift with peak power over 30 kW. The triple-hybrid system offers over 50% energy savings compared with Diesel or fuel-cell systems.

Supercapacitor-powered terminal tractors transport containers to warehouses. They provide an economical, quiet and pollution-free alternative to Diesel terminal tractors.

Light-rails and trams

Supercapacitors make it possible not only to reduce energy, but to replace overhead lines in historical city areas, so preserving the city's architectural heritage. This approach may allow many new light rail city lines to replace overhead wires that are too expensive to fully route.

In 2003 Mannheim adopted a prototype light-rail vehicle (LRV) using the MITRAC Energy Saver system from Bombardier Transportation to store mechanical braking energy with a roof-mounted supercapacitor unit. It contains several units each made of 192 capacitors with 2700 F / 2.7 V interconnected in three parallel lines. This circuit results in a 518 V system with an energy content of 1.5 kWh. For acceleration when starting this "on-board-system" can provide the LRV with 600 kW and can drive the vehicle up to 1 km without overhead line supply, thus better integrating the LRV into the urban environment. Compared to conventional LRVs or Metro vehicles that return energy into the grid, onboard energy storage saves up to 30% and reduces peak grid demand by up to 50%.

In 2009 supercapacitors enabled LRVs to operate in the historical city area of Heidelberg without overhead wires, thus preserving the city's architectural heritage. The SC equipment cost an additional €270,000 per vehicle, which was expected to be recovered over the first 15 years of operation. The supercapacitors are charged at stop-over stations when the vehicle is at a scheduled stop. In April 2011 German regional transport operator Rhein-Neckar, responsible for Heidelberg, ordered a further 11 units.

In 2009, Alstom and RATP equipped a Citadis tram with an experimental energy recovery system called "STEEM". The system is fitted with 48 roof-mounted supercapacitors to store braking energy, which provides tramways with a high level of energy autonomy by enabling them to run without overhead power lines on parts of its route, recharging while traveling on powered stop-over stations. During the tests, which took place between the Porte d’Italie and Porte de Choisy stops on line T3 of the tramway network in Paris, the tramset used an average of approximately 16% less energy.

In 2012 tram operator Geneva Public Transport began tests of an LRV equipped with a prototype roof-mounted supercapacitor unit to recover braking energy.

Siemens is delivering supercapacitor-enhanced light-rail transport systems that include mobile storage.

Hong Kong's South Island metro line is to be equipped with two 2 MW energy storage units that are expected to reduce energy consumption by 10%.

In August 2012 the CSR Zhuzhou Electric Locomotive corporation of China presented a prototype two-car light metro train equipped with a roof-mounted supercapacitor unit. The train can travel up 2 km without wires, recharging in 30 seconds at stations via a ground mounted pickup. The supplier claimed the trains could be used in 100 small and medium-sized Chinese cities. Seven trams (street cars) powered by supercapacitors were scheduled to go into operation in 2014 in Guangzhou, China. The supercapacitors are recharged in 30 seconds by a device positioned between the rails. That powers the tram for up to 4 kilometres (2.5 mi). As of 2017, Zhuzhou's supercapacitor vehicles are also used on the new Nanjing streetcar system, and are undergoing trials in Wuhan.

In 2012, in Lyon (France), the SYTRAL (Lyon public transportation administration) started experiments of a "way side regeneration" system built by Adetel Group which has developed its own energy saver named ″NeoGreen″ for LRV, LRT and metros.

In 2015, Alstom announced SRS, an energy storage system that charges supercapacitors on board a tram by means of ground-level conductor rails located at tram stops. This allows trams to operate without overhead lines for short distances. The system has been touted as an alternative to the company's ground-level power supply (APS) system, or can be used in conjunction with it, as in the case of the VLT network in Rio de Janeiro, Brazil, which opened in 2016.

Buses

The first hybrid bus with supercapacitors in Europe came in 2001 in Nuremberg, Germany. It was MAN's so-called "Ultracapbus", and was tested in real operation in 2001/2002. The test vehicle was equipped with a diesel-electric drive in combination with supercapacitors. The system was supplied with 8 Ultracap modules of 80 V, each containing 36 components. The system worked with 640 V and could be charged/discharged at 400 A. Its energy content was 0.4 kWh with a weight of 400 kg.

The supercapacitors recaptured braking energy and delivered starting energy. Fuel consumption was reduced by 10 to 15% compared to conventional diesel vehicles. Other advantages included reduction of CO2 emissions, quiet and emissions-free engine starts, lower vibration and reduced maintenance costs.

As of 2002[update] in Luzern, Switzerland an electric bus fleet called TOHYCO-Rider was tested. The supercapacitors could be recharged via an inductive contactless high-speed power charger after every transportation cycle, within 3 to 4 minutes.

In early 2005 Shanghai tested a new form of electric bus called capabus that runs without powerlines (catenary free operation) using large onboard supercapacitors that partially recharge whenever the bus is at a stop (under so-called electric umbrellas), and fully charge in the terminus. In 2006, two commercial bus routes began to use the capabuses; one of them is route 11 in Shanghai. It was estimated that the supercapacitor bus was cheaper than a lithium-ion battery bus, and one of its buses had one-tenth the energy cost of a diesel bus with lifetime fuel savings of $200,000.

A hybrid electric bus called tribrid was unveiled in 2008 by the University of Glamorgan, Wales, for use as student transport. It is powered by hydrogen fuel or solar cells, batteries and ultracapacitors.

Motor racing

The FIA, a governing body for motor racing events, proposed in the Power-Train Regulation Framework for Formula 1 version 1.3 of 23 May 2007 that a new set of power train regulations be issued that includes a hybrid drive of up to 200 kW input and output power using "superbatteries" made with batteries and supercapacitors connected in parallel (KERS). About 20% tank-to-wheel efficiency could be reached using the KERS system.

The Toyota TS030 Hybrid LMP1 car, a racing car developed under Le Mans Prototype rules, uses a hybrid drivetrain with supercapacitors. In the 2012 24 Hours of Le Mans race a TS030 qualified with a fastest lap only 1.055 seconds slower (3:24.842 versus 3:23.787) than the fastest car, an Audi R18 e-tron quattro with flywheel energy storage. The supercapacitor and flywheel components, whose rapid charge-discharge capabilities help in both braking and acceleration, made the Audi and Toyota hybrids the fastest cars in the race. In the 2012 Le Mans race the two competing TS030s, one of which was in the lead for part of the race, both retired for reasons unrelated to the supercapacitors. The TS030 won three of the 8 races in the 2012 FIA World Endurance Championship season. In 2014 the Toyota TS040 Hybrid used a supercapacitor to add 480 horsepower from two electric motors.

Hybrid electric vehicles

Supercapacitor/battery combinations in electric vehicles (EV) and hybrid electric vehicles (HEV) are well investigated. A 20 to 60% fuel reduction has been claimed by recovering brake energy in EVs or HEVs. The ability of supercapacitors to charge much faster than batteries, their stable electrical properties, broader temperature range and longer lifetime are suitable, but weight, volume and especially cost mitigate those advantages.

Supercapacitors' lower specific energy makes them unsuitable for use as a stand-alone energy source for long distance driving. The fuel economy improvement between a capacitor and a battery solution is about 20% and is available only for shorter trips. For long distance driving the advantage decreases to 6%. Vehicles combining capacitors and batteries run only in experimental vehicles.

As of 2013[update] all automotive manufacturers of EV or HEVs have developed prototypes that uses supercapacitors instead of batteries to store braking energy in order to improve driveline efficiency. The Mazda 6 is the only production car that uses supercapacitors to recover braking energy. Branded as i-eloop, the regenerative braking is claimed to reduce fuel consumption by about 10%.

Russian Yo-cars Ё-mobile series was a concept and crossover hybrid vehicle working with a gasoline driven rotary vane type and an electric generator for driving the traction motors. A supercapacitor with relatively low capacitance recovers brake energy to power the electric motor when accelerating from a stop.

Toyota's Yaris Hybrid-R concept car uses a supercapacitor to provide quick bursts of power.

PSA Peugeot Citroën fit supercapacitors to some of its cars as part of its stop-start fuel-saving system, as this permits faster start-ups when the traffic lights turn green.

Gondolas

In Zell am See, Austria, an aerial lift connects the city with Schmittenhöhe mountain. The gondolas sometimes run 24 hours per day, using electricity for lights, door opening and communication. The only available time for recharging batteries at the stations is during the brief intervals of guest loading and unloading, which is too short to recharge batteries. Supercapacitors offer a fast charge, higher number of cycles and longer life time than batteries.

Emirates Air Line (cable car), also known as the Thames cable car, is a 1-kilometre (0.62 mi) gondola line that crosses the Thames from the Greenwich Peninsula to the Royal Docks. The cabins are equipped with a modern infotainment system, which is powered by supercapacitors.

Images for kids

-

A micrograph of activated carbon under bright field illumination on a light microscope. Notice the fractal-like shape of the particles hinting at their enormous surface area. Each particle in this image, despite being only around 0.1 mm across, has a surface area of several square meters.

-

A scanning tunneling microscopy image of single-walled carbon nanotube

-

SEM image of carbon nanotube bundles with a surface of about 1500 m2/g

See also

In Spanish: Supercondensador para niños

In Spanish: Supercondensador para niños