Fiberglass facts for kids

Fiberglass (also called fibreglass and glass fibre) is material made from extremely fine fibers of glass.

It is used as a reinforcing material for many polymer products. The composite material, that is produced by this method is called "fiberglass" in popular usage. The proper names are fiber-reinforced polymer (FRP) or glass-reinforced plastic (GRP).

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of fiberglass was only made possible when finer tools for machines were produced.

Contents

Formation

Glass fiber is formed when thin strands of silica-based or other formulation glass is extruded into many fibers with small diameters that are suitable for textile processing. Glass is unlike other polymers because, even as a fiber, it has little crystalline structure (see amorphous solid). The properties of the structure of glass in its soft stage are very much like its properties when spun into fiber.

Applications

Fiberglass is an immensely versatile material due to its light weight, inherent strength, weather-resistant finish and variety of surface textures.

The development of fiber-reinforced plastic for commercial use was extensively researched in the 1930s. It was of particular interest to the aviation industry. A means of mass production of glass strands was accidentally discovered in 1932 when a researcher at Owens-Illinois directed a jet of compressed air at a stream of molten glass and produced fibers. After Owens merged with the Corning company in 1935, Owens Corning adapted the method to produce its patented "Fiberglas" (one "s"). A suitable resin for combining the "Fiberglas" with a plastic was developed in 1936 by du Pont. The first ancestor of modern polyester resins is Cyanamid's of 1942. Peroxide curing systems were used by then.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft radomes (fiberglass being transparent to microwaves). Its first main civilian application was for the building of boats and sports car bodies, where it gained acceptance in the 1950s. Its use has broadened to the automotive and sport equipment sectors. In production of some products, such as aircraft, carbon fiber is now used instead of fiberglass, which is stronger by volume and weight.

Advanced manufacturing techniques such as pre-pregs and fiber rovings extend fiberglass's applications and the tensile strength possible with fiber-reinforced plastics.

Fiberglass is also used in the telecommunications industry for shrouding antennas, due to its RF permeability and low signal attenuation properties. It may also be used to conceal other equipment where no signal permeability is required, such as equipment cabinets and steel support structures, due to the ease with which it can be molded and painted to blend with existing structures and surfaces. Other uses include sheet-form electrical insulators and structural components commonly found in power-industry products.

Because of fiberglass's light weight and durability, it is often used in protective equipment such as helmets. Many sports use fiberglass protective gear, such as goaltenders' and catchers' masks.

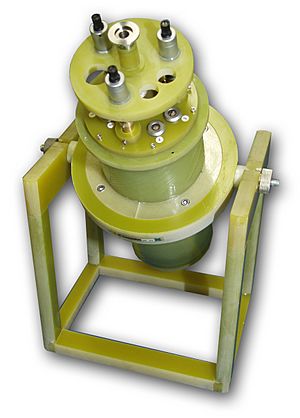

Storage tanks

Storage tanks can be made of fiberglass with capacities up to about 300 tonnes. Smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fiber, with the fiber orientation at right angles to the hoop stress imposed in the side wall by the contents. Such tanks tend to be used for chemical storage because the plastic liner (often polypropylene) is resistant to a wide range of corrosive chemicals. Fiberglass is also used for septic tanks.

House building

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

Piping

GRP and GRE pipe can be used in a variety of above- and below-ground systems, including those for:

- Desalination

- Water treatment

- Water distribution networks

- Chemical process plants

- Firewater

- Hot and Cold water

- Drinking water

- Wastewater/sewage, Municipal waste

- Natural gas, LPG

Examples of fiberglass use

- DIY bows / youth recurve; longbows

- Pole vaulting poles

- Equipment handles(Hammers, axes, etc.)

- Traffic lights

- Ship hulls

- Rowing shells and oars

- Waterpipes

- Helicopter rotor blades

- Surfboards, tent poles

- Gliders, kit cars, microcars, karts, bodyshells, kayaks, flat roofs, lorries

- Pods, domes and architectural features where a light weight is necessary

- High-end bicycles

- Auto body parts, and entire auto bodies (e.g. Lotus Elan, Anadol, Reliant, Quantum Quantum Coupé, Chevrolet Corvette and Studebaker Avanti, and DeLorean DMC-12 underbody)

- Antenna covers and structures, such as radomes, UHF broadcasting antennas, and pipes used in hex beam antennas for amateur radio communications

- FRP tanks and vessels: FRP is used extensively to manufacture chemical equipment and tanks and vessels. BS4994 is a British standard related to this application.

- Most commercial velomobiles

- Most printed circuit boards consist of alternating layers of copper and fiberglass FR-4

- Large commercial wind turbine blades

- RF coils used in MRI scanners

- Drum Sets

- Sub-sea installation protection covers

- Reinforcement of asphalt pavement, as a fabric or mesh interlayer between lifts

- Helmets and other protective gear used in various sports

- Orthopedic casts made with fiberglass are completely waterproof, allowing patients to bathe, shower, and swim while wearing a cast. The waterproof cast cover stays tightly around the cast and prevents water from ever reaching it while the patient is in contact with water. The cover can easily be removed to dry, and can be re-used often.

- Fiberglass grating is used for walkways on ships and oil rigs, and in factories

- Fiber-reinforced composite columns

- Water slides

Safety

Bare fiberglass can cause skin irritation and cuts when handled without gloves. There have been concerns that fiberglass can be accidentally inhaled into the lungs, where it can cause cancer and other lung problems, similar to asbestos. Fiberglass has been called "man-made asbestos". Substitutes for fiberglass building insulation, such as cellulose and aerogel, have started to appear.

Related pages

Images for kids

-

Fiberglass statue, copy of antique Roman bronze statue of winged Victory in the Santa Giulia museum in Brescia.

See also

In Spanish: Plástico reforzado con vidrio para niños

In Spanish: Plástico reforzado con vidrio para niños